The DIMIDE Difference: Quality

Today it is getting harder and harder to buy a quality tool. Go to your local harbor freight or other tool store and you'll find a wall of clamps for sale that each cost only a few dollars thanks to their use of cheap materials and foreign manufacturing. While these tools may have an absurdly low up-front cost, the added costs over time of replacing the tools when they break, the frustration over their lackluster performance, and their inability to deliver when a job gets even slightly demanding, makes it hard to even justify their cheap price tag.

Due to most clamp's weak structure caused by their use of plastics, low-strength metals, and minimization of material, manufacturers limit the amount of torque users can apply. Today's most common solution is to use frustratingly small T-handles that limit the lever arm to prevent over-torquing. However, most users still experience clamp arms twisting or screw threads being stripped. If you tried to simply weld a hex head onto one of these clamps and use an impact wrench, you would likely strip the screw or shear the hex off from torsion.

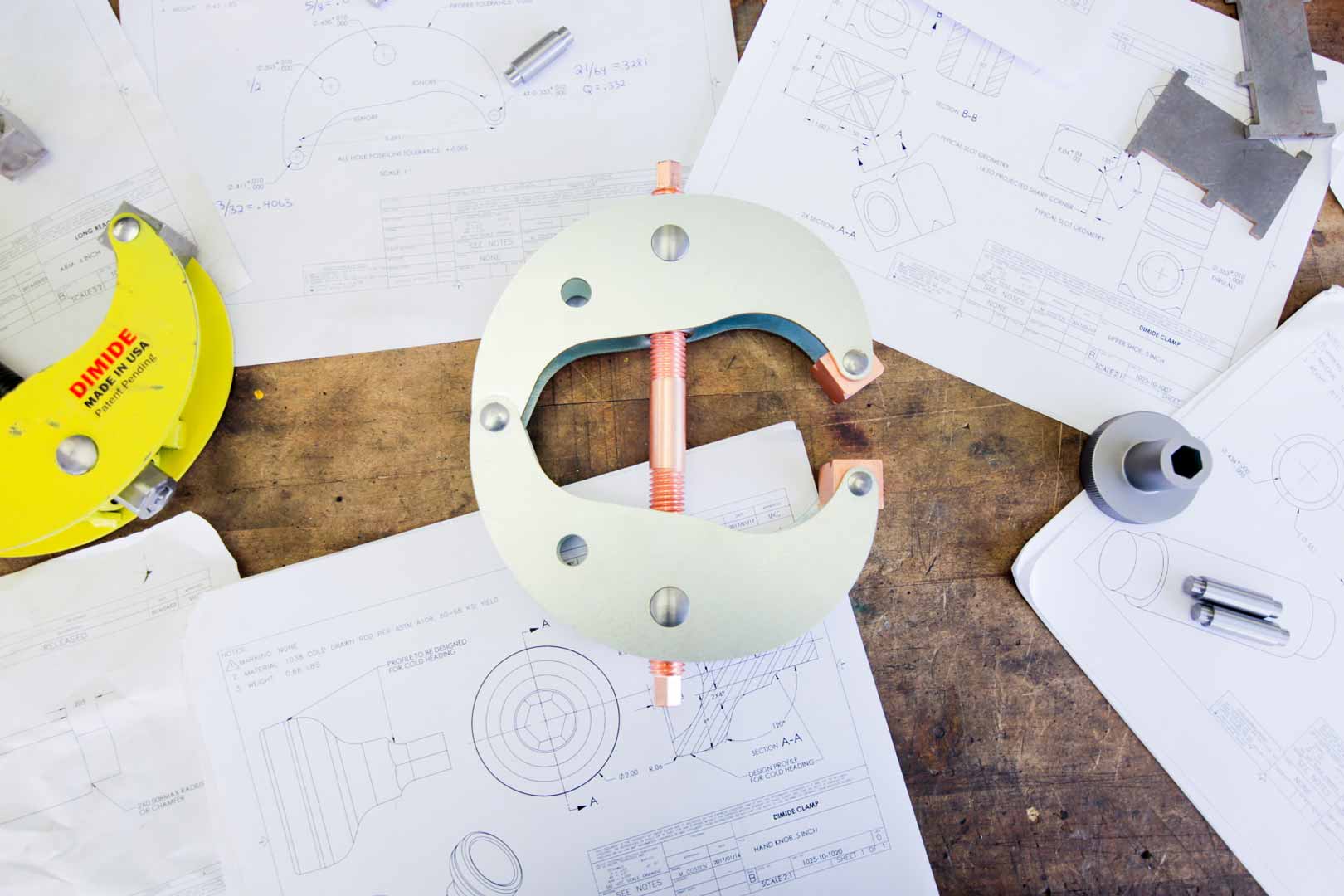

This is where the DIMIDE Clamp is different. Thanks to its patent-pending design, the arms do not twist under loading due to the added shear plates. This allows the clamp to handle much higher loads, over 7,000 lbs, prior to deforming. Also, DIMIDE's unique screw uses ultra-high strength steel, a hardened hex, specially engineered threads, and is loaded in tension to easily handle impact wrench loads as great as 400 ft-lbs without stipping, deforming, or buckling. To further help prevent the destruction of the clamp, if you load it beyond it's rated load, the arms will visibly yield letting you know to back off the torque prior to the screw being damaged. Should the arm be plastically deformed the only change would be an increased clamp capacity. This is opposed to many other clamps where you risk buckling the screw, shearing the screw in torsion, or stipping the threads which can quickly turn a cheap but adequate clamp into an expensive paperweight.

Above shows a brief demonstration of the advantage the DIMIDE Clamp delivers. The DIMIDE Clamp effortlessly delivers over 5,000 lbs of clamp load using a 400 ft-lbs impact wrench while the Kant-Twist and its small handle makes the user struggle to only deliver 1,700 lbs. For more examples, visit our video page.