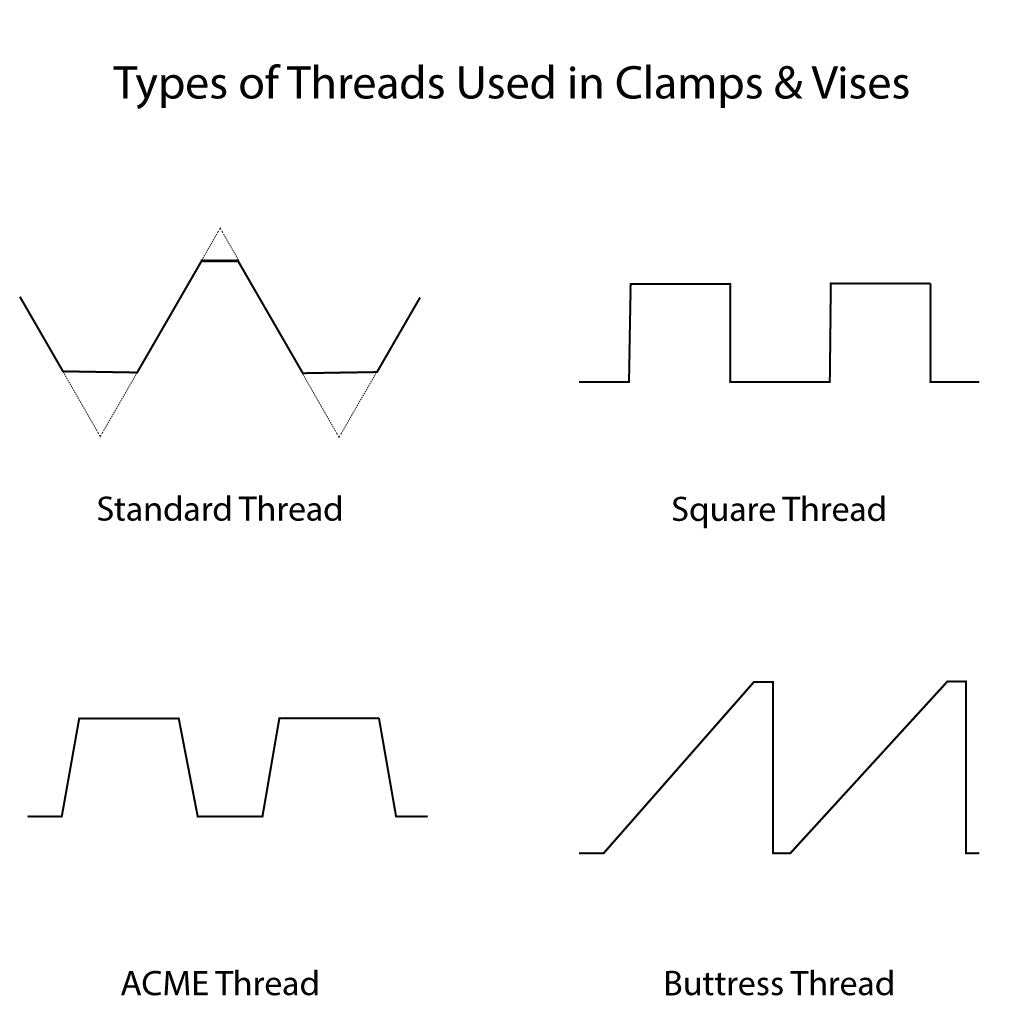

Screw Thread Types And Their Benefits

Standard Threads

Pros

- Increased minor pitch diameter (shaft diameter)

- Higher-strength

- Increased linear force for equal torque

- Reduced linear actuation per rotation

- Manufacturability

- Accepted standardized dimensions

- May be used with off the shelf components

Cons

- Slower clamping speed

- Greater number of threads per axial distance

- Reduced thread strength depending upon thread size

Square Threads

Pros

- Lower number of threads per axial distance

- Increased clamping speed

- Low friction

- High power transfer efficiency

Cons

- Reduced minor pitch diameter

- Reduced strength

- Reduced thread root cross-section

- Vulnerable to wear & thread stripping

- Difficult to manufacture

- Significantly increased cost

- No strong standard for dimensions

- Typically requires high-cost custom components

ACME Threads

Pros

- Increased clamping speed

- Lower number of threads per axial distance

- Manufacturability

- Increased thread shear capacity

Cons

- Reduced Shaft Diameter & Strength

- Greater Cost

- Weak standard sizing

Buttress Threads

Pros

- Increased clamping speed

- Lower number of threads per axial distance

- High thread strength in one direction

- Greatest thread shear capacity

Cons

- Only designed to be loaded in one direction

Clamp Thread Types

Standard Threads | Unified Thread Standard (UTS)

Standard threads typically have increased numbers of threads per inch which decreases linear screw motion per turn of the screw compared to ACME, Square, and Buttress threads. However, standard threads typically have an increased shaft diameter which delivers increased strength. Standard threads include coarse, fine, and extra-fine variations. Standard threads with their increased number of threads per inch also allow for an increased linear force at the same amount of torque when compared to Square, ACME, or Buttress threads.

Coarse Threads (UNC)

Coarse threads or UNC threads have the fewest number of threads per axial length of all standard threads. This means that a nut will move linearly further per each rotation. This means a clamp with this style of a screw will tighten faster. The downside is that due to the large thread size, there is a reduced shaft diameter which leads to a reduction in shaft strength. The increased thread size increases thread shear strength.

Fine Threads (UNF)

Fine threads or UNF threads have more threads per axial length compared to coarse threads. Fine threads deliver increase strength through a greater shaft diameter but are slower to tighten.

Extra Fine Threads (UNEF)

Extra fine threads or UNEF threads have more threads per axial length compared to fine threads. Extra Fine threads deliver the highest strength through having the greatest shaft diameter but are the slowest to tighten. Another potential downside is that extra fine threads can potentially lead to tolerance issues due to how small their threads are.

Root Radius Threads (UNJC, UNJF, UNJEF)

Standard threads have a squared root at the inner diameter of the thread as shown in the featured image. However, a tight corner tends to create high-stress concentrations and can lead to stripping of a screws thread. To prevent this a root radius is used on UNJ threads which eliminates the high-stress concentration by providing a fillet or rounded corner. To prevent interference issues while allowing adequate thread overlap between the internal and external threads, only the external threads, the threads on the screw, require a root radius.

Square Threads

Square threads are commonly used as lead screws due to a greater efficiency compared to ACME threads while also having a lower number of threads per inch. The square thread allows for a reduced power loss to friction

Due to the reduced manufacturability and thread strength of square threads compared to an ACME thread they are less commonly used in clamps and vises and instead used in more industrial power translation applications where increased efficiency matters the most.

ACME Threads

ACME threads are commonly used in clamps, vises, and linear actuators. The main advantage to an ACME thread is a low number of threads per inch. This allows ACME threads to allow for increased linear actuation per turn of screw which is similar to a square thread. The difference between square threads and ACME threads is the angled root of the ACME thread. The angled root allows for ACME threads to be more easily manufactured compared to the square root of a square thread. The root of an ACME thread is also larger which delivers increased strength in preventing stripping and wear of the thread. It should be noted that the typical controlling failure mechanism of a screw is torsional shear which is based on the minor diameter of a screw and not on the type of thread.

ACME screws are modified a lot since they are cut with a single-point tool meaning there isn't a largely accepted standard controlling the design of ACME threads. Manufacturers many times will shorten an ACME thread to a stub in order to increase the minor diameter of the screw and in turn deliver increased strength. However, since there is only so much one can reduce height of a thread without running into issues, a standard fine thread still will typically have a greater minor diameter and therefore offer greater strength.

Buttress Threads

Buttress threads are specifically designed to handle high axial thrust in one direction. Buttress threads also typically have a higher number of threads per inch which allows increased linear screw motion per turn of the screw similarly to an ACME and Square thread. Buttress threads are as efficient as a square thread in the direction which they are designed to apply load while being easier to manufacture.

Manufacturing Methods

Cut Threads

Pros

- Low tooling cost

- Good for low volume, and prototype screws

- Can be used to manufacture square threads

Cons

- Higher cost per screw

- Reduced strength compared to rolled threads

Cut threads have a reduced upfront cost since they can be cut by a large variety of machines. This makes machining threads to be the preferred manufacturing method for lower volumes and prototypes.

Square threads can also only be machined, and are difficult to machine due to the lacking of a relief angle.

Rolled Threads

Pros

- High production rate

- Low cost per screw at high volumes

- Increased strength and fatigue life

Cons

- High upfront cost

- Requires higher production volumes

- Leaves a root radius

- Needs to be factored in the design for clearance

- Can also be noted as a pro since it increases strength

Thread rolling has a lot of advantages over thread cutting including high production rate, increased strength and durability, and reduced cost per screw.

The downside of rolling threads is the high upfront tooling and setup costs which make thread rolling require high production volumes. Another potential downside is that thread rolling leaves a rounded root or a root radius in the screw which needs to be taken into account when determining design clearance between the screw and whatever it is driving. The root radius does, however, deliver increased strength and resistance to wear by eliminating high-stress concentrations at the root of a thread.

Dimide's Screw Threads

The screw is the most critical component of a clamp. The screw is what converts torque into clamp force. A lot goes into making sure Dimide's screws are built to last.

Strength

First, to obtain the strength needed for impact wrench loading without driving costs through the roof, we use a standard fine or extra-fine thread. These threads allow for a maximized minor diameter to deliver the greatest screw strength. We then use our higher volume to allow for rolled threads which deliver even further strength and durability. The rolled thread also provides a root radius preventing threads from stripping delivering increased screw strength. The selected screw provides greater thread shear strength compared to shaft strength which provides a more obvious failure mechanism to provide safety while clamping critical components. However, prior to the screw failing in anyway the clamp has been designed to show side plate bending. The design has been tested for a lifetime of use with 1/4" impact drivers, and strength concerns are only required for those who have interested in additional load beyond the 2,000 lbs electric impact drivers deliver. Dimide also offers the HD series clamp which is compatible with more powerful 1/2" electric impact wrenches which delivers over 5,000 lbs of clamp force.

Speed

To make up for the slow speed fine and extra fine threads, Dimide employs the use of a turnbuckle drive system along with a configuration that allows for an increased tightening rate. With this system, Dimide achieves a rate of tightening far faster and stronger than any acme, buttress, or square thread screw. The Dimide clamp delivers one inch of clamping tightening per 4 to 6 turns of the screw. To obtain an equivalent tightening speed a C or F Clamp would need to use a 1-Inch Diameter ACME screw which would be substantially more expensive.

Impact Compatible

If the manual tightening speed of the Dimide Clamp wasn't fast enough all the effort that has gone into delivering a high strength screw has allowed for impact driver/wrench compatibility. This allows for nearly instant high-force clamping.

Material

The Dimide screw also uses high-strength hardened Chromoly Steel to deliver the performance and durability our impact compatible clamps have become known for.